- #CRYOVAC 8600 MANUAL UPDATE#

- #CRYOVAC 8600 MANUAL DRIVER#

- #CRYOVAC 8600 MANUAL MANUAL#

- #CRYOVAC 8600 MANUAL SOFTWARE#

- #CRYOVAC 8600 MANUAL CRACK#

of phases Frequency Energy consumption per hour (average) Installed power Current protection 400 V 3 + earth 50 Hz 5.0 kwh 6.5 kw 35 Amp slow (curve D ) Vacuum Vacuum pumps 1 x 630 m 3 /h for 1 st stage and 1 x 630 m 3 /h m 3 /h booster for 2 nd stage (Depending on packaging speed, product type and pipe length) 4ĥ 3.4 Working characteristics Product dimensions Length 650 mm max. 3.3 Utilities Compressed air Electrical Quality (ISO8573-1:2001) Class Class when using oils containing esters Class when equipment is used below 5 C Pressure 0.6 MPa (6 bar) Connecting type G ½ external thread Consumption 24 Nm 3 /h Connecting fitting Flexible pipe, 12.5 mm inside diameter Voltage No. 2-1, Layout LR (product flow left to right) 3Ĥ 3 Nominal technical data 3.1 Machine dimensions Length, width & height See machine layout 3.2 Weight 2300 kg approx.

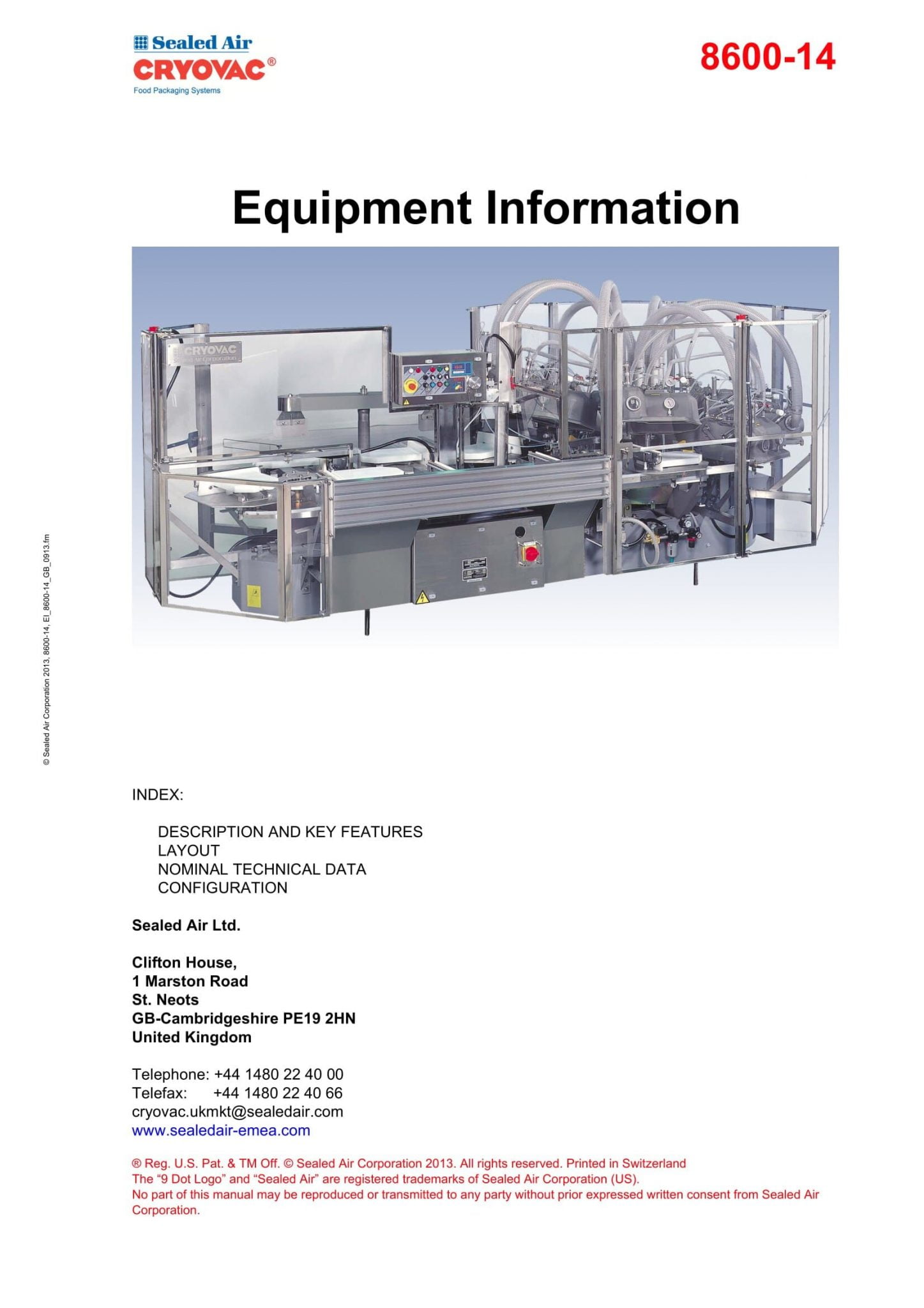

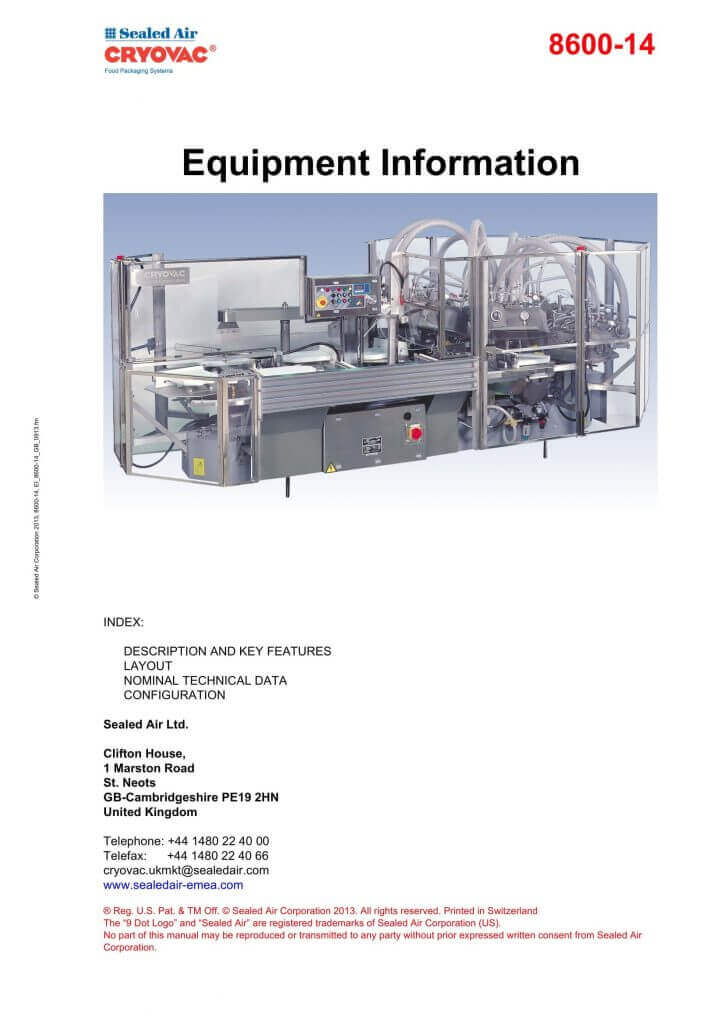

1.2 Key features Rotary chamber vacuum packaging machine requiring only 1 operator Machine achieves up to 30 products/min Cross vacuum system shares vacuum between chambers to increase speed and reduce power consumption Product elevator on platen Air-cooled sealbars Sealbars on platen Speed controlled by inverter Powered pre-cut knives Motor located directly at large sprocket Rotary valve on top of large sprocket Soft discharge function Easy and fast changeovers to different products, shapes and sizes Complies with all relevant EU safety and hygiene regulations Good access for maintenance New on E - Versions Central lubrication system Vacuum sensor and digital vacuum display Digital seal control - more accurate reading Stepless seal amperage adjustment Display with diagnostic messages Scratchproof metal safety guards 2ģ 2 Layout Fig. Designed with ergonomics safety and hygiene in mind it is easy to use and clean, simple to maintain and meets all relevant European legislation for safety and hygiene. All critical parts are treated against the corrosive environment often found in food production and packaging rooms. Its main characteristics are: Six rotary chambers provide a continuous supply of products at variable speed, up to 30 packages/minute Changing to different products, shapes and sizes is performed quickly and with no need for special tools Soft discharge for sensitive products Bag width up to 450 mm (nominal) Construction is simple and robust. The 8600E-18 is the large, high productivity version and is typically used for fresh red meat cuts or large processed meat products. They can be used for a wide range of products, such as: processed meat, poultry, cheese and smaller fresh red meat cuts.

#CRYOVAC 8600 MANUAL MANUAL#

No part of this manual may be reproduced or transmitted to any party without prior expressed written consent from Sealed Air Corporation.Ģ 1 Description and key features 1.1 Description The Cryovac 8600 series machines are part of the range of highly successful Cryovac rotary chamber vacuum packaging machines. Printed in Switzerland The 9 Dot Logo and Sealed Air are registered trademarks of Sealed Air Corporation (US). Sealed Air Corporation All rights reserved. Neots GB-Cambridgeshire PE19 2HN United Kingdom Telephone: Telefax: Reg. rom More manual about flashrom can be found.1 8600E-18 Equipment Information INDEX: DESCRIPTION AND KEY FEATURES LAYOUT NOMINAL TECHNICAL DATA CONFIGURATION Sealed Air Ltd. Use the parameter -p dediprog to force flashrom to use SF100.Įxample: flashrom -p dediprog -r biosimage.

#CRYOVAC 8600 MANUAL SOFTWARE#

The latest software can be downloaded from. Using SF100 Windows Dediprog provide the USB software tool chain under windows. The programmer is easily controlled by USB bus.

#CRYOVAC 8600 MANUAL UPDATE#

#CRYOVAC 8600 MANUAL DRIVER#

That the software is properly installed with the updated version and the USB driver is. 31 MB: : Software: Linux software for SF100, SF600 and SF600Plus Support Linux OS.

#CRYOVAC 8600 MANUAL CRACK#

Windows Server 2012 Terminal Services Licensing Crack on this page.

0 kommentar(er)

0 kommentar(er)